This guide outlines how to design and define a custom temperature probe. It covers how to define cable and tail lengths and the parameters that need to be defined for a successful new temperature probe design. If you need a custom temperature probe or design advice please contact us

Temperature range

The temperature range is a crucial factor to provide for a custom temperature probe because it will affect the selection of capsule and type of cable.

Therefore provide the temperature the cable and the temperature sensing probe will be exposed to.

Cable length

Determine the ideal cable length for a comfortable and easy connection from the media into the equipment.

Sometimes requesting a longer cable length can make the temperature probe more versatile for slightly different field connection conditions.

remember that it is easier for installers and stock organisation to order a longer length to achieve all variations of distance (within reason) and to cut down as required rather than to stock specific cable lengths for different cable runs.

The diagram below demonstrates the terminology and drawing example of a temperature probe. The element inside the capsule can be a Thermistor RTD or Digital temperature sensor

Temperature Element

There are 3 main types of temperature sensors used in temperature probes ranked in order of popularity.

- RTD PT100 or PT1000

- Thermistor NTC or PTC (Normally NTC)

- Digital temperature sensor, these can vary on type of protocol.

The required element is a fundamental factor when building the custom temperature probe. It underpins the technology used to determine the temperature so is a crucial detail.

The temperature sensing technology will be defined by the device reading the temperature. The input to this temperature reader or circuit will specify the type of sensor required.

RTD

If it is and RTD sensor it will be a PT100 or PT1000. It is easy to determine which one it is with a quick test of the resistance, if the reading is in the hundreds, it’s a PT100 if in the thousands it’s a PT1000.

For an RTD temperature element the below points need to be considered

- Accuracy class

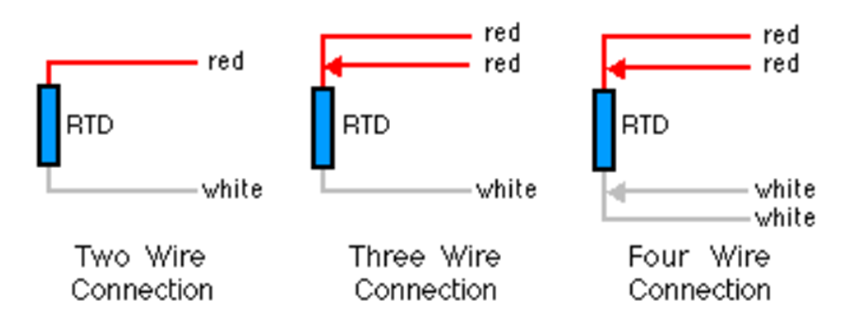

- Wire connection e.g. 2 wire 3 wire 4 wire

- PT100 or PT1000

Thermistor

This requires an entire section to itself as the nominal resistance at 25 degrees Celsius can vary with different models.

For a custom thermistor element probe the following needs to be defined

- Resistance at 25 degrees C

- Beta value common examples are 3977K 3435K

- Accuracy

- NTC or PTC

NTC resistance increases as temperature decreases.

PTC resistance increases and temperature increases.

Digital temperature element

To use a digital temperature element the points below will need to

- Part number

- Protocol

Common digital temperature probe protocols are I2C , One wire, SPI and RS485

- Wiring detail

The above guidance will speed up the design process and avoid oversights in the custom probe design. For any assistance please leave a comment or drop us a line