This guide will overview what an RTD is and how they are made and measured.

What is an RTD temperature sensor?

RTD stands for Resistance Temperature Detector. it is a temperature sensor element which changes electrical resistance when the temperature changes. this change in resistance is used to calculate the temperature.

The RTD’s resistance increases linearly (in comparison to a thermistor at least) when the temperature increases.

Some RTDs are called wire wound because they consist of fine platinum wire wrapped around a ceramic or glass core.

Typically RTD elements are housed in a protective probe for protection from the environment they are exposed to make them more robust.

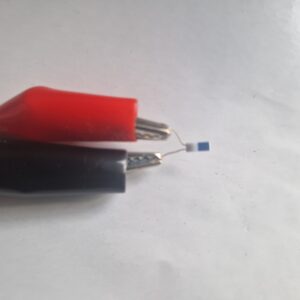

Example of RTD Protective Casing

Inexpensive RTDs are called thin film RTDs. They consist of a base ceramic with a fine Platinum track deposited on it. So far we found out what is resistance temperature detector, so let’s now explore how does an RTD work?

How does a resistance thermometer work?

An RTD comprises of a resistance element and insulated Platinum wires.

RTDs may have 3 or even 4 wires to increase accuracy by reducing the electrical resistance of the wires the RTD is connected to.

Platinum is used to manufacture RTDs because it is stable and has a linear relationship between temperature and resistance, chemical resistance and a wide operating temperature range.

RTD working principle

The RTD has a simplistic principle. As the temperature of the platinum increases the resistance to the flow of electricity also increases.

An electrical current is passed through the RTD Temperature sensor, as the temperature changes so does the electrical resistance. using ohms law and electronic principles the temperature can be calculate from circuit analysis.

Electrical resistance is measured in Ohms. The resistance value can then be converted into temperature based on the characteristics of the element. The thermal response time for an RTD is between 0.3 and 5 seconds, the more protection the RTD element has the longer the thermal response time will be.

RTD sensors types

Resistance Temperature Detectors RTDs have 2 different varieties. This is defined by the type of construction of the temperature element. The two different types aredetailed below

Thin-film RTDs

The thin-film RTD elements are made by depositing a thin layer of metal which in most cases is platinum on a ceramic substrate material. The metal film is laser cut or etched into an electrical circuit pattern that provides the specified amount of resistance. Lead wires are then attached, and a thin protective glass coating is applied to the entire element.

The advantages of thin-film RTDs are that they are reliable and are produced at a low cost. Moreover, they are more damage resistant from vibrations than the other types of resistance temperature detectors.

Wire-wound RTDs

The other type of RTD is wire-would. Its sensing element comprises a small coil of ultra-thin platinum wire. The wire coil is commonly packaged inside a ceramic or glass tube or the wire can be wound around the outside of a ceramic or glass housing material.

Advantages of wire-wound RTD

The advantages of wire-wound RTDs are that they are very accurate and those with glass cores can readily be immersed in many liquids, while those with ceramic cores can be used to accurately measure extremely high temperatures.

Disadvantages of wire-wound RTD

The disadvantages of wire-would RTDs are that they are more expensive to produce than thin-film and they are more vibration-sensitive

Resistance temperature detector (RTD) applications

The RTD sensors are primarily used in the following industries:

- Industrial electronics

- Consumer electronics

- Medical electronics

- Aerospace

- Military

- Automotive

- Power electronics

How to test an RTD temperature sensor?

To test a RTD sensor set the multimeter to measure resistance .

Measure across the terminals of the RTD the element or the wires

visit the dedicated guides with calculators and converters for the PT100 or PT1000 RTD’s